Product Line

Primary Uses

Outside-Plant & Inside Plant cabling

Building wire and Communications

Cable (including CAT5, CAT6, and CO-AX)

Fiber Optic Cable (single mode, multi-mode and POF)

Stranded speaker wire

Hose & Tubing

Connectors & Capacitors

Reel-in-the-box packaging

Rope

Ribbon and Tape

STAPLED Assembly

Our STAPLED Reels are the optimal low cost alternative to plywood reels. With elongated drive holes, an assortment of center arbor hole sizes, and custom core notching, these reels can accommodate a large variety of manual and automated winding equipment. The integrated stacking tabs keep full pallets of product stable during transport. Our STAPLED reels range from 11” up to 14” and are made to customer specified traverse lengths.

DEAD~BOLT® Assembly

The line of DEAD~BOLT® Reels are robust reel able to handle heavier loads than our economical Stapled reels. Bolts engage directly into the flanges, eliminating the need for nuts and creating a rapid assembly system allowing us to send components that our customers can assemble quickly, as needed. With an assortment of drive holes and center arbor hole sizes, and custom core notching, these reels can accommodate a large variety of manual and automated winding equipment. The integrated stacking tabs keep full pallets of product stable during transport. Our line of DEAD~BOLT® Reels range from 11.75” up to 23.75” with a variety of core diameters on select sizes. All reels are made to customer specified traverse lengths.

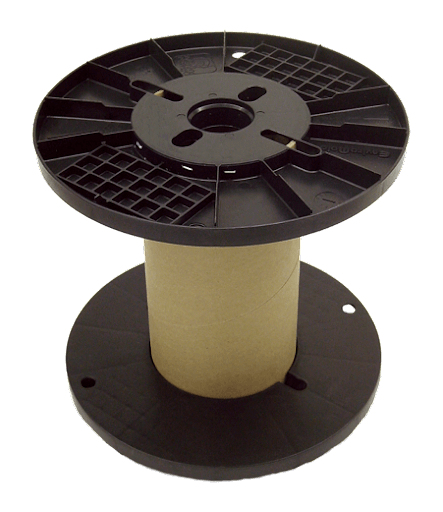

ALL~PLASTIC Assembly

These economical reels are made through a Spinweld process that creates a strong bond between the flanges and core. This allows for better waste management and recycling. We offer these in 6.5” diameter and 10.5” diameter, and all reels are made to customer specified traverse lengths.

3~FLANGE Assembly

3~FLANGE Reels are the clear cut choice for fiber optic cables. These products utilize the DEAD~BOLT® rapid assembly method for our most secure assembly. Our most popular products provide a molded-in notch in the center flange for a smooth debris-free transition area. These are available in flange diameters of 14”, 19.75” and 23.75”. We also have the capability to provide traditional die-cut notching. All reels are made to customer specified traverse lengths.

END~STANDS (for boxed reel packaging)

Our END~STANDS for Reel-In-A-Box packaging are the ideal for product requiring increased protection and convenient hands-free de-spooling. The stands feature our EZ~BRAKE® System for adjustable payout tension, reducing product free-spooling and tangling due to backlash. These stands are a perfect compliment to select sizes of our STAPLE, DEAD~BOLT® and ALL~PLASTIC Reels.

LABOR~SAVER™ Automation Ready Reel System

This is a complete REEL and END~STAND system fully assembled at our facility and ready for fully automated winding and packaging equipment. The END~STANDS are locked into position at assembly making the reel ready to load into the machine without any extra labor. After packaging, a simple pull of the wire unlocks the REEL from the END~STANDS, allowing the product to de-spool freely.